We provide surface treatment of parts as a bonus for our customers, who value deliveries from a single location. Our galvanisation shop is certified for galvanising components for the automotive industry according to the requirements of the DIN EN ISO 9001:2000 and ISO/IATF 16949:2009 standards.

We apply zinc coatings three different ways.

1. galvanisation with suspension and bulk technology (Fe/Zn 5-25 μm – thick-film passivation, blue passivation without Cr6+ without sealing, with sealing).

2. suspension galvanisation (Fe/Zn 5-25 μm – black passivation without Cr6+, with or without sealing).

3. suspension alloyed galvanisation, zinc-nickel (Fe/ZnNi 5-20 μm – transparent and black passivation, with sealing).

The dimensions of our suspension technology are 1600 x 600 x 800 mm (l x w x h). The maximum dimensions of suspended galvanised parts are 1300 x 270 x 800 mm.

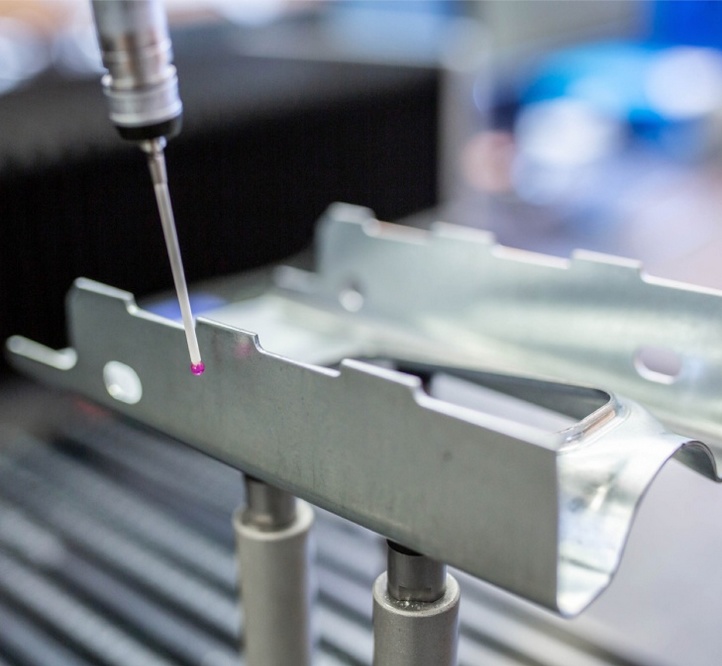

We keep a close eye on the entire process – our line’s software enables automatic regulation and monitoring of parameters, including back traceability and printing of route sheets. We measure the prescribed thickness with a FISCHERSCOPE X-RAY XDL® 230. We test the corrosion resistance of our products in saliferous fog in accordance with SS DIN 50 021 and EN ISO 9227.

We always fully throw ourselves into our work with enthusiasm – and it doesn’t matter how complicated the problem we are facing may be. We are well aware that quality is the most important criterion in our field.